123 Social Green Housing by SOMOS Arquitectos

Trang 1 trong tổng số 1 trang

04112009

123 Social Green Housing by SOMOS Arquitectos

123 Social Green Housing by SOMOS Arquitectos

Madrid practice [You must be registered and logged in to see this link.] have completed a social housing project in Madrid, Spain.

Called 123 Social Green Housing, the eight-storey building incorporates 123 apartments.

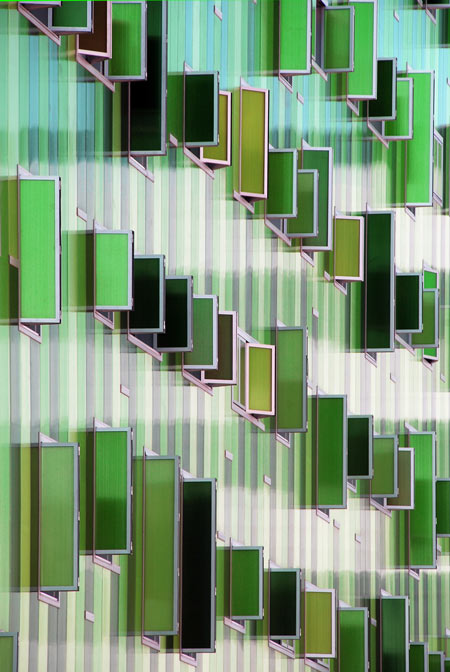

The building’s exterior is clad in plastic panels on aluminium frames, in three shades of green.

Windows are shaded by 369 shutters in six types, also made of polycarbonate and aluminium.

Two entrances lead to one hall with mail boxes arranged on terraces.

An internal courtyard with steel galleries and staircases provides access to apartments.

Dark grey metal surounds the ground floor with apartments elevated

two metres above street level, while white penthouses crown the top of

the building.

The project is part of the same development as Celosia Residence by MVRDV and Blanca Lleó ([You must be registered and logged in to see this link.]).

Here’s some more information from SOMOS Arquitectos:

–

WORK TITLE: 123 SOCIAL GREEN HOUSING IN VALLECAS (MADRID). SPAIN.

SMALL DESCRIPTION

This social housing project in Madrid has an original facade design

with polycarbonate panels in three hues of green. In fact, it is one of

the first residential projects which features plastic materials as a

skin. The programme, including 123 social housing apartments, is called

to be one of the new urban icons on the outskirts of Madrid.

1. MEMORY

The project rises eight floors above the ground along one of the

limits of the block imposed by the restrained urban planning. The great

scale of the building forces it to act as a visual screen for the green

area that stands aside, physically protecting it. The volume,

specifically fixed according to the rigid city-planning rules that

prevail within the scope of the PAU de Vallecas and the optimization of

the space to obtain the highest amount of apartments asked by the

developer, drove us to respect the enveloped volume determined in the

planning, using other tools to give a new urban approach to the

intervention. Thus, the facade remains as one of the most powerful

instruments to manipulate the perceptive scale.

As we will specify later, colours, sizes and displacements for the

openings are regarded with attention. The ground floor is a delicate

area, as it must deal with the street, separating car and pedestrian

entrances. The apartments in this floor are oriented towards the so

called green area and they have been raised two metres from street

level in order to provide them with some extra isolation from the view

of the possible passer-by. The official facade opens towards the hustle

and bustle common of a commercial street with a four lane road running

along. It gathers the commercial premises and the three accesses

(parking in and out and pedestrian).

Even though the number of apartments demanded two separate accesses,

we decided to create a single welcome space which would be big enough

to interact with the scale of the building. This hall area is

completely open on both sides and its rectangular shape establishes a

dialogue with the free-form platforms of the mailbox area. Thus, the

entrance is modulated by means of generous terrasses finished with

vitreous mosaic, prepared for the installation of the mailboxes, which

grow in height emphasizing the landing as a highly compressed space,

where you’re almost able to touch the plastic semispheres.

These transitions of scale are unified through a green ceiling

completely illuminated with the so called network of protruding

lights-skylight.

The building poses reflections dealing with the scale reduction,

bringing a friendly relation with the surroundings. The facade is split

into small coloured units that are combined with each other and are

able to transmit a changing sensation, a dynamic chameleon-like skin.

The volume crystallizes through open celled polycarbonate panels fixed

over aluminum profiles, creating a sustainable and recyclable skin,

whose properties will be identified later in detail. These panels use

the gradation of tones and brightness with a substrate of neutral color

determined by the outer shell of the facade, achieving the right

combination of both materials in order to make the entire facade to

vibrate, entering in resonance with that light so characteristic on the

city of Madrid.

Instead of the common window roll-up blind, we have designed

specific shutters for the project. Three-hundred and sixty-nine

openings fixed through six different types. They open outwards and fold

until they rest perpendicular to the facade. They have been made in

aluminium and finished with the same open celled polycarbonate panels

used in the facade.

They are designed as an integral solution, pre-assembled in a

factory, already arriving to the working site as a completely finished

unit which comprises all necessary elements (framing, hinges, doors..)

to settle it up within the facade, thus simplifying the layout on site.

They have two possible positions which change the perception of the

volume. Completely closed they seem to merge within a monolithic volume

giving continuity to the vertical strips. Completely opened they are

transformed into unequal colored fins giving the façade much more

plasticity.

The ground floor is enveloped by a dark grey metal skin which gives

weight to the changing green volume. The building is topped by the

penthouses finished in white which seem to blur with the clear skies.

In the inside, a long courtyard flanked with access galleries provides

the apartments with light and crossed ventilation, helping them to

become completely open to two opposed facades. The light galleries made

out of steel wind through the inner void and optimize the ratio of

vertical access cores on each floor. As added values, they grant

hygiene and salubrity to the common space of relation.

Translucent, polycarbonate hung ceilings are settled like linen

cloths that illuminate the accesses to the apartments. They also

conceal the electrical wiring and provide diffused light. The slim

stairs are solved extending out from these galleries in an overhang

which jumps in the air connecting each floor. In order to capture as

much light as possible, everything is finished is white with several

touches of colour on the windows and on the elevator fronts. Floors in

galvanized steel is suitable for outdoor use and helps to reflect light

into the courtyard. We have considered a mixed structural solution. The

main body of the building is solved in reinforced concrete, whereas the

circulation system of galleries and the stairs in the courtyard are

solved in steel.

2. CONSTRUCTION AND SUSTAINABLE CRITERIA.

The outer skin of the building poses an innovating solution through

the extensive use of a material with high energy-saving benefits: the

OPEN-CELLED POLYCARBONATE, which until now hadn’t been applied in

social housing, where the cost factor of €/m2 is absolutely decisive

and limited.

We are employing 40 millimeters thick open celled extruded

polycarbonate panels with seven internal walls and six air chambers,

protected against U.V. rays. Its modulation is 500mm wide and variable

length, only limited by the transportation conditions, arriving in this

particular case at 11 meters.

This celled structure helps to give the panel much more resistance

to flexion. Each item is fixed side by side by means of a male-female

joint, a device which allows the panels to be installed without a

second vertical order of aluminium profiles, avoiding therefore the

heat dispersion from the inner camera due to the thermal bridges

created by the structure.

Panel color finish is chosen using the RAL color system which helps

to give accurate match between panels, using three different tinted

tones of green which have been specially produced for this design. The

polycarbonate panel’s choice emerges as an important technical

improvement which as a whole offers important advantages:

ENERGETIC EFFICIENCY: it is an extruded material, its outer face is

protected from U.V. rays. Its six internal channels divided by walls

form air chambers within the panel, creating another extra thermal

chamber, thus increasing the insulating power of the original brick

facade in a very high percentage. The male-female joint assembly allows

the suppression of the vertical profiles. Due to the height of the

panels, this joint is secured at specific points by aluminium clips,

diminishing therefore the heat dispersion produced by thermal bridges

of the skin. Also, this material contributes improving other skin

qualities, for example, enhancing its sound insulation, again

increasing the original values.

ECOLOGICAL: as ecological qualities we should point out his recyclebility, the low amount of energy used on manufacturing and

transportation, its high degree of purity and mixing with different raw

materials, and its high degree of industralization in production and

assembly. The material offers a 10 year guarantee.

EASYNESS AND ECONOMY OF POSITIONING ON WORKSITE: its great

lightness, between 10 and 12 times less from the weight of glass with

equal thickness, allows to optimize manpower in its assembly and run

times. Its high level of prefabrication reduces costs for preparation

of material.

IMPACT RESISTANCE: thanks to its structure combining six cells, it

owns great impact resistance and an optimal behavior to flexion.

FACTORY FINISHING: the panels come out perfectly sealed from the

factory with an opaque aluminum tape on its upper end and another

micro-perforated aluminum tape on its lower end in order to allow

correct ventilation, avoiding inner staining and being protected from

possible fungus.

–

Posted by Rose Etherington from dezeen.com

Similar topics

Similar topics» House in Martindale Country Club / Alric Galindez Arquitectos

» Tori Tori Restaurant by Rojkind Arquitectos and Hector Esrawe

» Phim Green Building đây !

» Zafra-Uceda by NO.MAD Arquitectos

» Gimme Shelter by Rojkind Arquitectos for Ordos 100

» Tori Tori Restaurant by Rojkind Arquitectos and Hector Esrawe

» Phim Green Building đây !

» Zafra-Uceda by NO.MAD Arquitectos

» Gimme Shelter by Rojkind Arquitectos for Ordos 100

Permissions in this forum:

Bạn không có quyền trả lời bài viết|

|

|